High purity hydrogen gas generators

Standard information

-

Our HK series was developed as a supply source of high purity hydrogen gas required for use by flame ionization detectors (FID) and flame photometric detectors (FPD). The HK series is an innovative maintenance-free dryer system in a compact size that can generate high purity hydrogen safely and easily.

In order to generate high purity hydrogen gas with a hydrocarbon (HC) concentration of 0.1 ppm or less, the gas-chromatograph (GC) baseline in the HK series is very low and stable.

Features

- Maximum flow rate: 160 to 250 ml/min.

- Hydrogen gas with a purity of 99.999% or more can be supplied stably, and it is ideal for use as a combustion gas.

- Replacement of desiccant is not required.

- Long-term use is possible only by providing pure water.

- Safe use is possible even in rooms with hydrogen gas cylinder regulations.

- Hydrogen gas pressure inside and outside the unit is constantly monitored to ensure a high level of safety. The unit automatically stops even in the event of leaks outside the equipment (such as leaks in connected equipment or connection piping).

- Certified service personnel are available nationwide to assure that customers can use our products with confidence.

Specification

Standard Specification

| Model number | Purity (%) |

HC content (ppm) |

Flow rate (ml/min.) |

Outlet pressure (kPa) |

Water quality | Water tank size(ℓ) | Power supply | Ambient temperature and humidity | Unit dimension DWH (mm) |

Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|

| HK-Plus 250 | 99.999 | <0.1 | 250 | 700 | Pure water or Ultra pure water |

2 | AC100V/2.0A | Temperature:15~35℃ Humidity:0~80% ※No condensation |

230×360×430 | 20 |

※横スクロールで全体を表示

The specifications on this page may change without notice.

Ultra-high purity hydrogen gas generators

Standard information

-

NM-Our NM-Plus series was developed for use with analyzers requiring ultra-high purity hydrogen gas, such as gas-chromatograph (GC) carrier gas and combustion gas for flame ionization detectors (FID). The use of a hydrogen carrier gas is the technique that most closely achieves high-speed and high-resolution analysis for gas-chromatograph applications.

Our NM-Plus series can easily and safely generate ultra-high purity hydrogen gas.

Features

- Maximum flow rate: 100 to 1000 ml/min.

- Provides a stable supply of hydrogen gas with a purity of 99.99996% or more. Ideal for applications requiring a carrier gas or combustion gas.

- Solid polymer electrolyte membrane (PEM) is used for the electrolysis cell. In addition, the unit is maintenance free as it uses a dryer that does not require desiccant replacement.

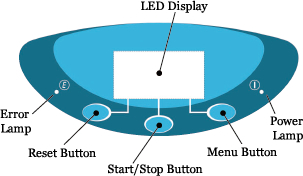

- Various alarm functions and an automatic stop function are provided. The unit automatically stops when an error occurs due to operation outside the setting range, or when an abnormality occurs inside or outside the equipment.

- Built-in vibration sensor automatically stops the unit when it detects shaking from an earthquake or other causes.

- Various usage options are also available such as interconnection of multiple units, RS-232C connection and PC connection.

- Certified service personnel are available nationwide to assure that customers can use our products with confidence.

Specification

Standard Specification

| Model number | Purity (%) |

Flow rate (ml/min.) |

Outlet pressure (kPa) |

Water quality | Water tank size(ℓ) | Power supply | Ambient temperature and humidity | Unit dimension DWH (mm) |

Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| NM-Plus 100 | 99.99996 | 100 | 900 | Pure water or Ultra pure water |

2 | AC100V/1A | Temperature:15~40℃ Humidity:0~80% ※No condensation |

230×360×430 | 14 |

| NM-Plus 160 | 99.99996 | 160 | 900 | 2 | AC100V/1.2A | 230×360×430 | 14 | ||

| NM-Plus 250 | 99.99996 | 250 | 900 | 2 | AC100V/1.65A | 230×360×430 | 15 | ||

| NM-Plus 300 | 99.99996 | 300 | 900 | 2 | AC100V/2.05A | 230×360×430 | 15 | ||

| NM-Plus 500 | 99.99996 | 500 | 900 | 2 | AC100V/2.2A | 230×360×430 | 16 | ||

| NM-Plus 600 | 99.99996 | 600 | 900 | 2 | AC100V/2.55A | 230×360×430 | 16 | ||

| NM-Plus 1000 | 99.99996 | 1000 | 900 | 2 | AC100V/3.85A | 230×360×430 | 17 |

※横スクロールで全体を表示

The specifications on this page may change without notice.